Non-destructive testing—the power of NOT breaking things.

Our experienced and knowledgeable staff use advanced technology to

thoroughly and accurately perform inspections.

- Area

Onahama・Izumi

- Industrial Parks-

TORYOKENSA CO., LTD.

Products & Services

-

Image Processing

-

Measurement / Analysis

Related Fields

-

Decommissioning

-

Energy / Environmental Recycling

-

Robots / Drones

Company Overview

Our company conducts inspections of equipment, devices, and materials for various plants (power, petroleum, chemical, and gas) during construction, along with regular maintenance inspections (various non-destructive testing and measurements) to ensure safe operations.

We also manage comprehensive safety operations for facilities handling nuclear fuel materials.

Additionally, we respond to requests to investigate and clarify the causes of defects in facilities and factories that are not legally required to be inspected. More recently, we have also provided videos taken with drones (aerial and underwater) and high-sensitivity videoscopes.

Primary Products / Services

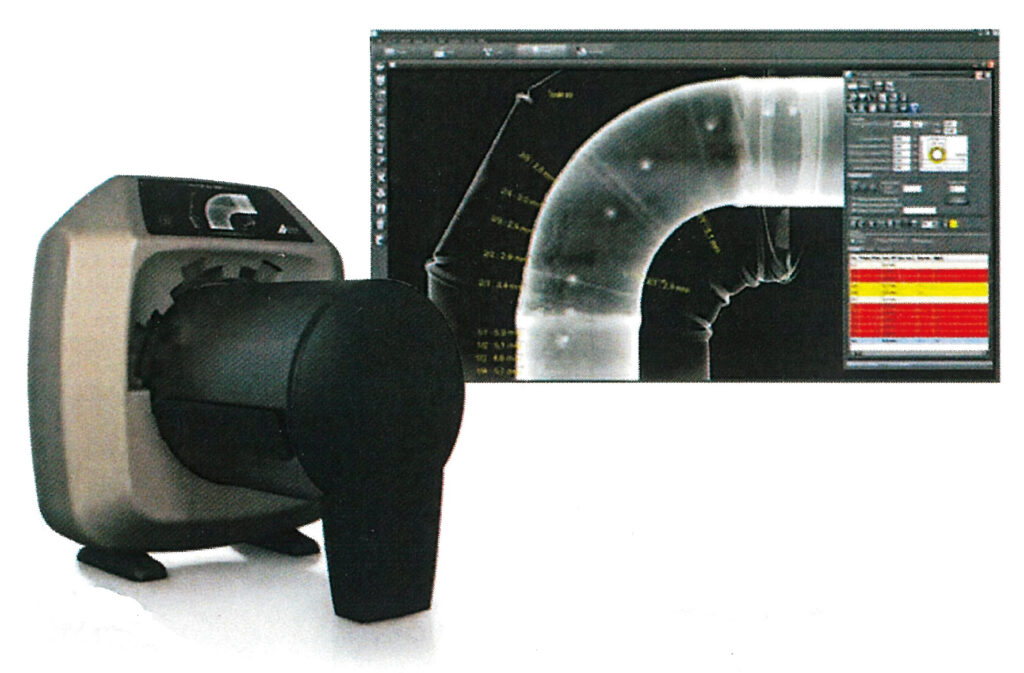

●General non-destructive testing, radiographic testing (RT)

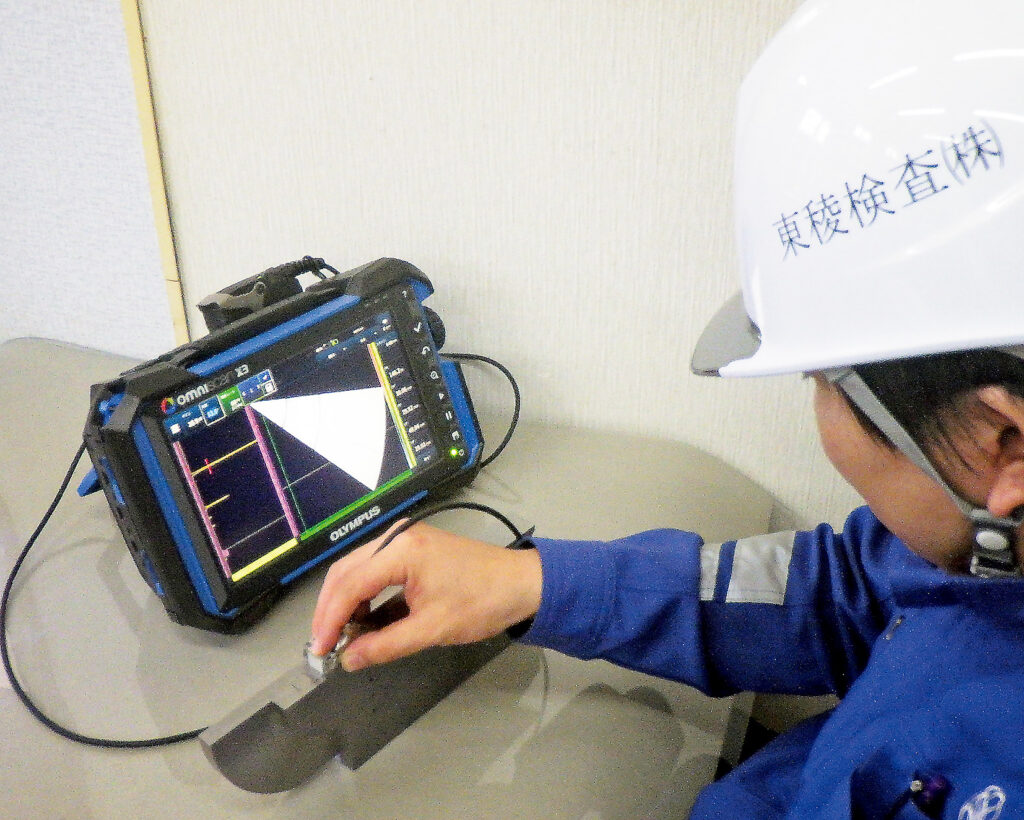

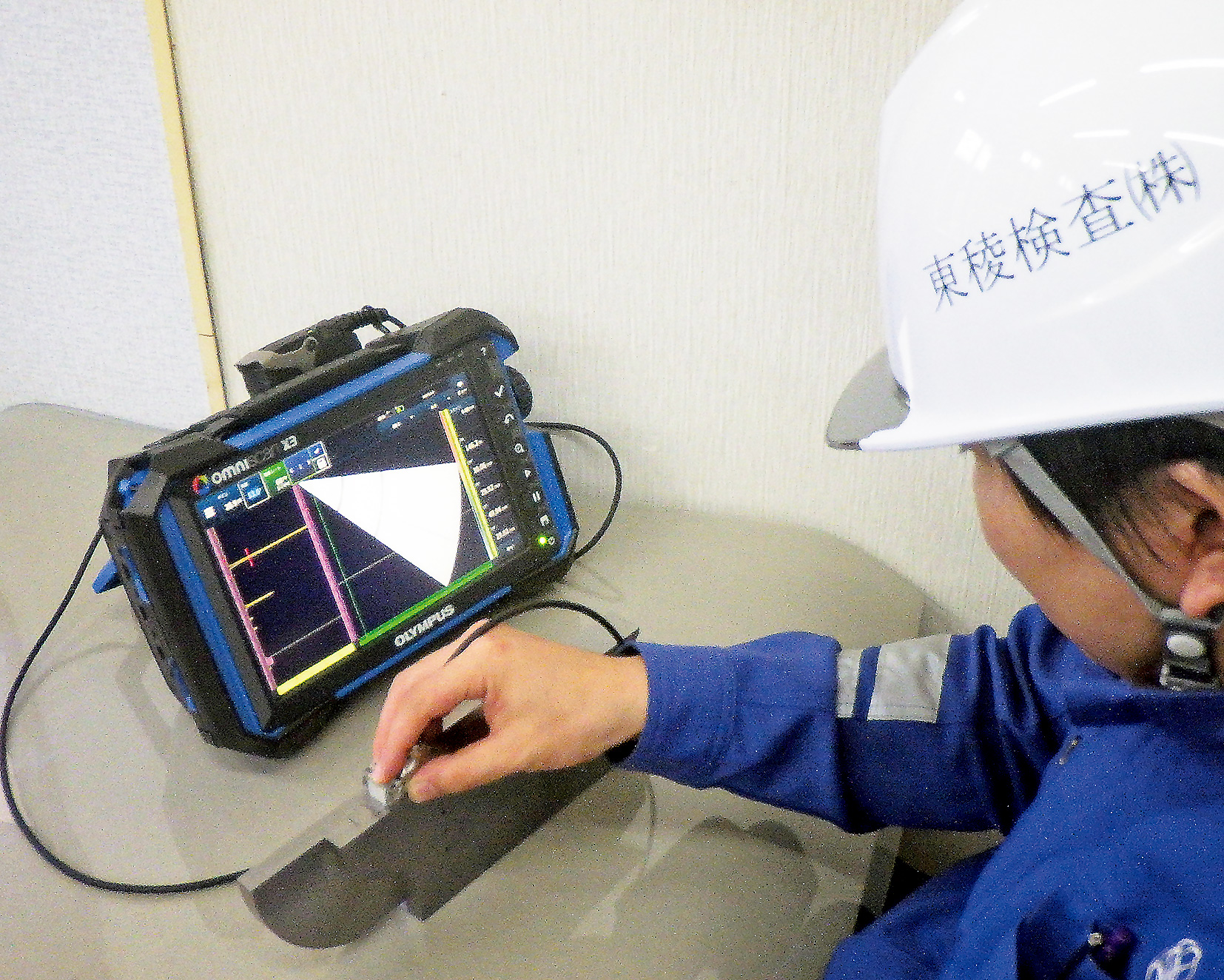

●Ultrasonic testing (UT)

●Magnetic particle testing (MT)

●Penetrant testing (PT)

●Electromagnetic induction testing (ET)

●Infrared thermography testing (TT)

●Vacuum leak testing

●Visual inspection

●Concrete reinforcement testing

●Various measurements

●Technician dispatch (quality, radiation, and construction management)

IP & Licenses, etc.

Certifications / Licenses

●Class D Member of JSNDI, the Japanese Society for Non-Destructive Inspection (RT · UT · MT · PT · ET · TT)

●Class D Member of JANDT, the Japanese Association for Non- Destructive Testing Industry (Reinforcement Detection)

●Radiation Protection Supervisors (Second Class)

●Chief of Radiography with X-rays

●Operations Chief of Radiography with Gamma-rays

●JUIDA Unmanned Aircraft Pilot License (Drones)

Company Strengths & Characteristics

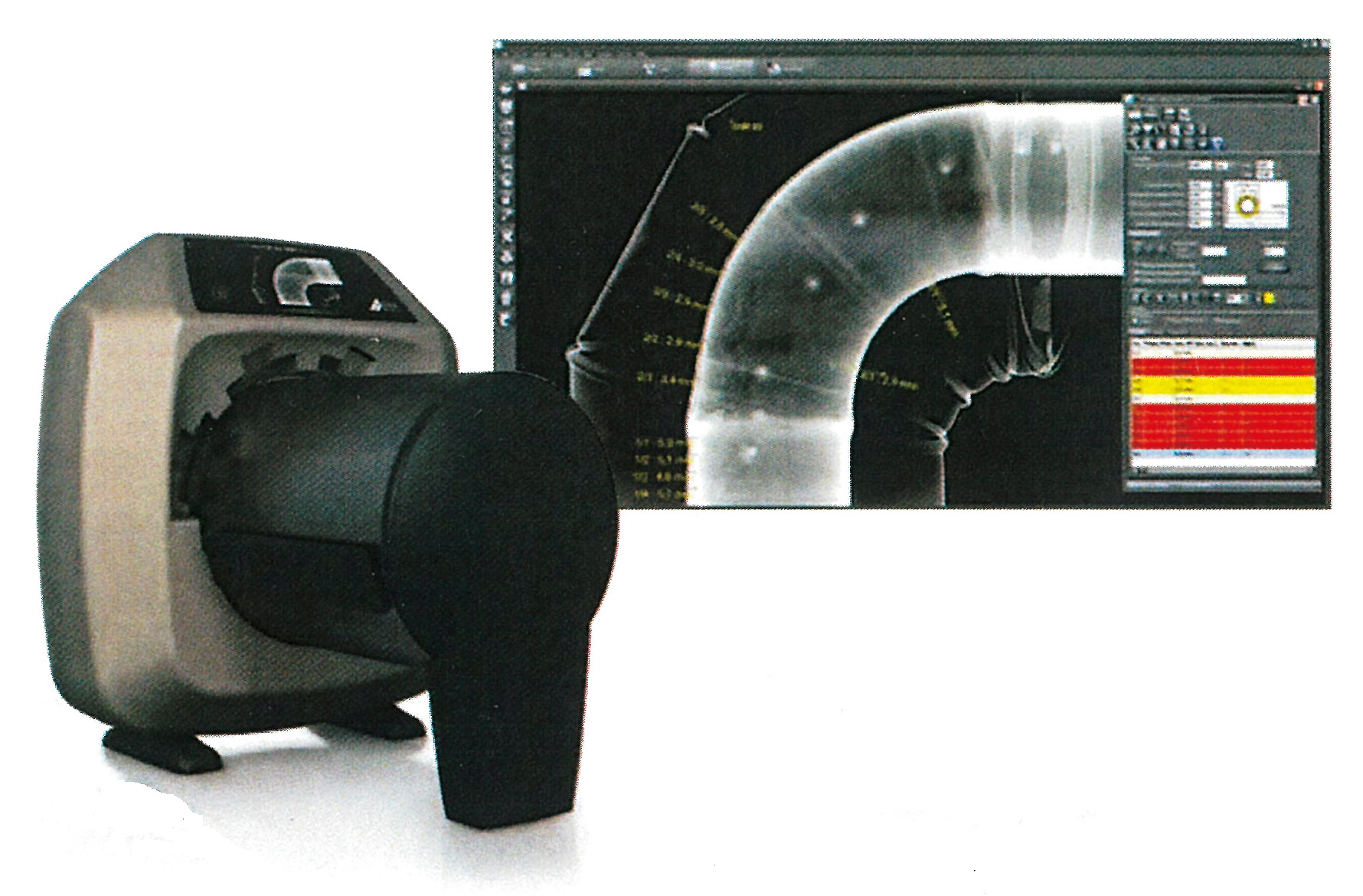

The industry still relies predominantly on analog image processing using X-ray devices for radiographic testing. By introducing digital imaging scanner equipment, our company ensures safety both for the environment (waste liquid during the treatment process) and the physical safety of workers (reduced radiation exposure). In ultrasonic testing, we utilize phased array ultrasonic flaw detectors, enabling us to provide technical support for various maintenance activities in power generation facilities, including wind and hydroelectric power. We also carry out concrete reinforcement testing, using electromagnetic induction, as well as infrared thermography testing.

Future Prospects & Areas of Interest

Many companies left the nuclear field after the 2011 earthquake. We entered the field in 2014 at the request as a local business.

With the push for the restart of power generation facilities, we hope to play a large role in ensuring the maintenance field is safe. At the same time, as a local business, we hope to take part in decommissioning efforts, taking a neutral position and working to make sure local residents can live with peace of mind.

We also plan to involve ourselves in the expansion of wind power generators with sufficient preparation, knowledge and experience in their maintenance.

Electric power is crucial to Japan’s industries, and pushes for carbon neutrality and zero carbon production will greatly change with the operation of renewable and nuclear energy systems. Non-destructive testing will be a key way to ensure any serious problems with these systems are managed beforehand. Our hope is to put our keen and discerning eyes to work providing safety and security.

Company information

TORYOKENSA CO., LTD.

-

Address

〒971-8111

1-9 Ohara Rokutanda-machi, Onahama, Iwaki-shi, Fukushima

(Inspection Technology Center) 39 Kubo-sorimachi, Kashima-machi, Iwaki-shi, Fukushima 971-8144

-

TEL

0246-53-6322

-

FAX

0246-53-6422

-

E-mail

-

URL

http://www.toryokensa.co.jp

Copyright ©︎2024 IWAKI MANUFACTURING COMPANY ARCHIVE All Rights Reserved.