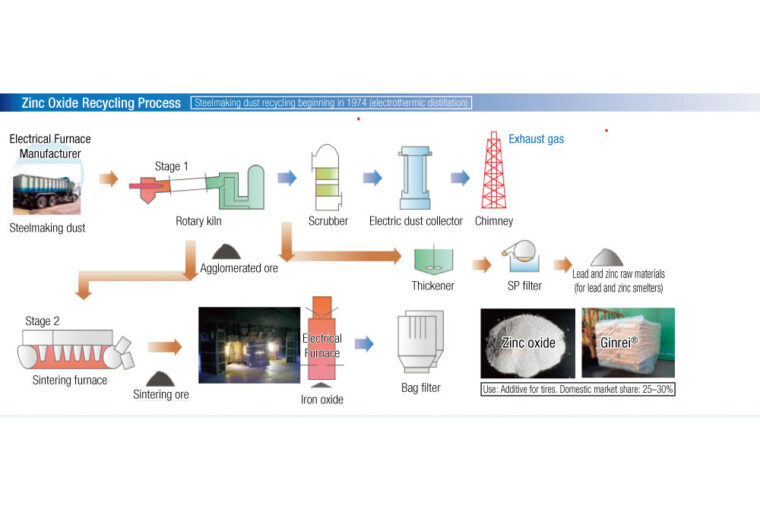

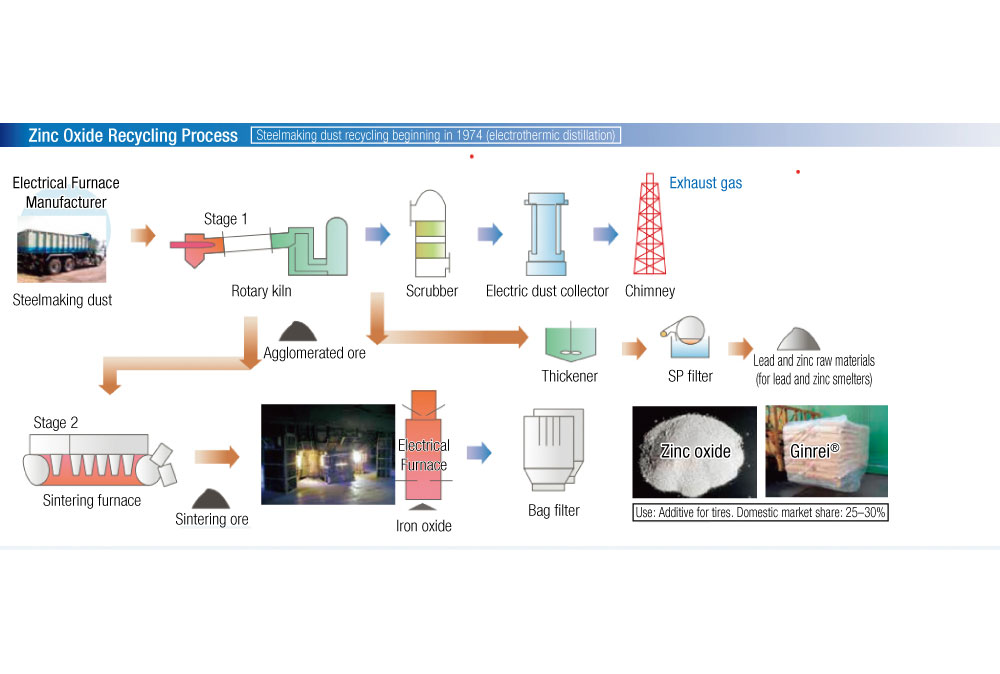

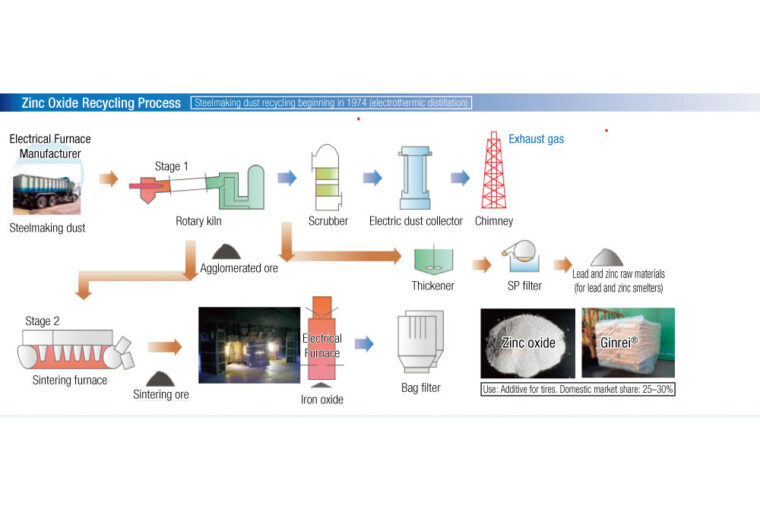

Zinc Oxide Process

Sulfuric acid tanks

We contribute to society with our advanced metal refinery skills and mindfulness towards material recycling.

- Area

Onahama・Izumi

- Industrial ParksOnahama Rinkai Industrial Park

Toho Zinc Co., Ltd. Onahama Refinery

Related Fields

-

Energy / Environmental Recycling

Company Overview

In 1963 our company began roasting zinc ore and producing sulfuric acid. In 1974, we became the first company in Japan to commercialize the recovery and production of zinc oxide from electric furnace dust.

Since then, we have developed into two divisions: the Zinc Business Division and the Environmental Recycling Division. Today we play a role in promoting a circular economy through the dedicated recycling of valuable metals.

Primary Products / Services

●Zinc ore, sulfuric acid, zinc oxide “Ginrei (R)”� Our zinc oxide product is called “Ginrei (R)” and is sold to major tire manufacturers. Zinc oxide is essential as a vulcanization accelerator in rubber production, playing a critical role in enhancing its elasticity.

IP & Licenses, etc.

Intellectual Property

●2011 Patent No. 4845800 Winding Inductor and Manufacturing Method

●2013 Patent No. 5358562 Method for Manufacturing Composite Magnetic Materials and the Composite Magnetic Materials

●2014 Patent No. 5638456 Method and Apparatus for Treating Perchlorate Ion-Containing Solution Patent No. 5412425 Composite Magnetic Material and Manufacturing Method

●2015 Patent No. 5718794 Method for Treating Perchlorate Ion- Containing Solution

●2016 Patent No. 5948637 Metal Recovery Method

●2017 Patent No. 6208782 Dynamic Vibration Absorber and Floor Patent No. 6060206 Ring Coil

●2020 Patent No. 6706729 � Three-phase Inductor and Manufacturing Method

Certifications / Licenses

●2001 ISO14001 certified

●2002 ISO9001 certified

●2023 ISO45001 certified

●Industrial Waste Treatment License

●Specially Controlled Industrial Waste Treatment License

Company Strengths & Characteristics

●Our main raw material, zinc concentrate, is sourced from our own mines in Australia or imported from South America. It is then roasted and transported to the Annaka smelter as zinc sintered ore. We also produce and sell sulfuric acid from the by-products of roasting.

●In our zinc recycling business, when scrap iron is melted in an electric furnace, dust containing zinc called “steelmaking dust” is generated. Zinc is recovered from this steelmaking dust and sold as zinc oxide. We have created these proprietary manufacturing technologies thanks to our 40+ years of experience and are the only company in the world that can manufacture this.

Future Prospects & Areas of Interest

With a focus on recycling non-ferrous metals, our company has become a leader in the development of advanced environmental technologies.

The valuable metal resources we recover are transformed into high- quality recycled products that contribute to society, supporting enriched and comfortable living for the future. Our company is also exploring adjustments to the energy sources used in our electric furnaces as part of our goal of achieving a carbon-neutral society.

Company information

Toho Zinc Co., Ltd. Onahama Refinery

Copyright ©︎2024 IWAKI MANUFACTURING COMPANY ARCHIVE All Rights Reserved.