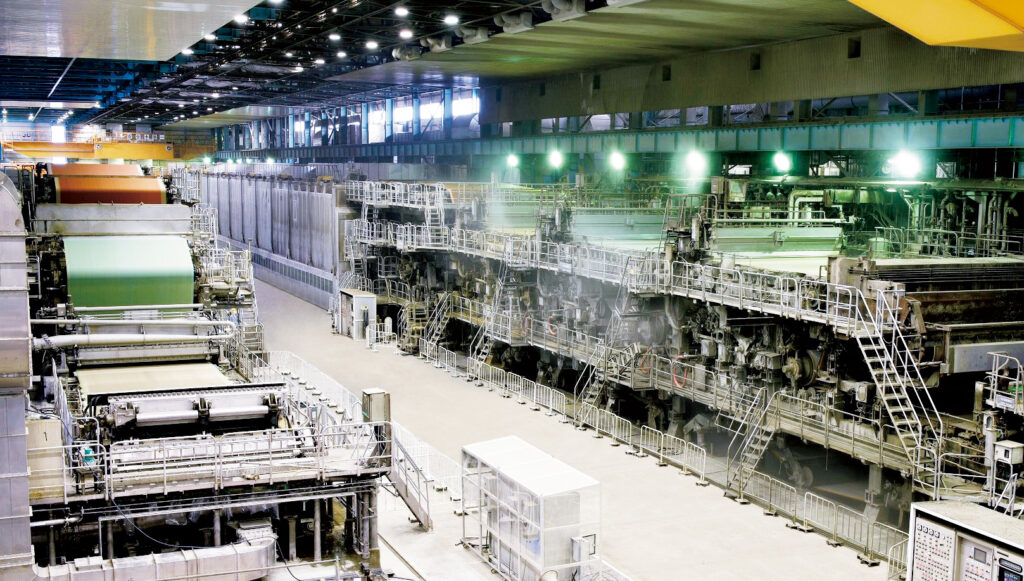

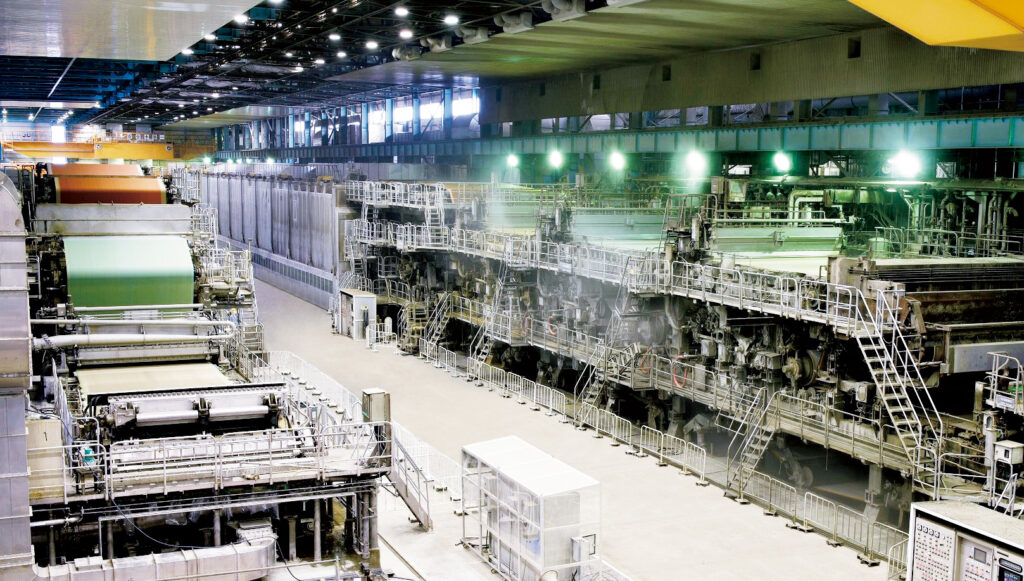

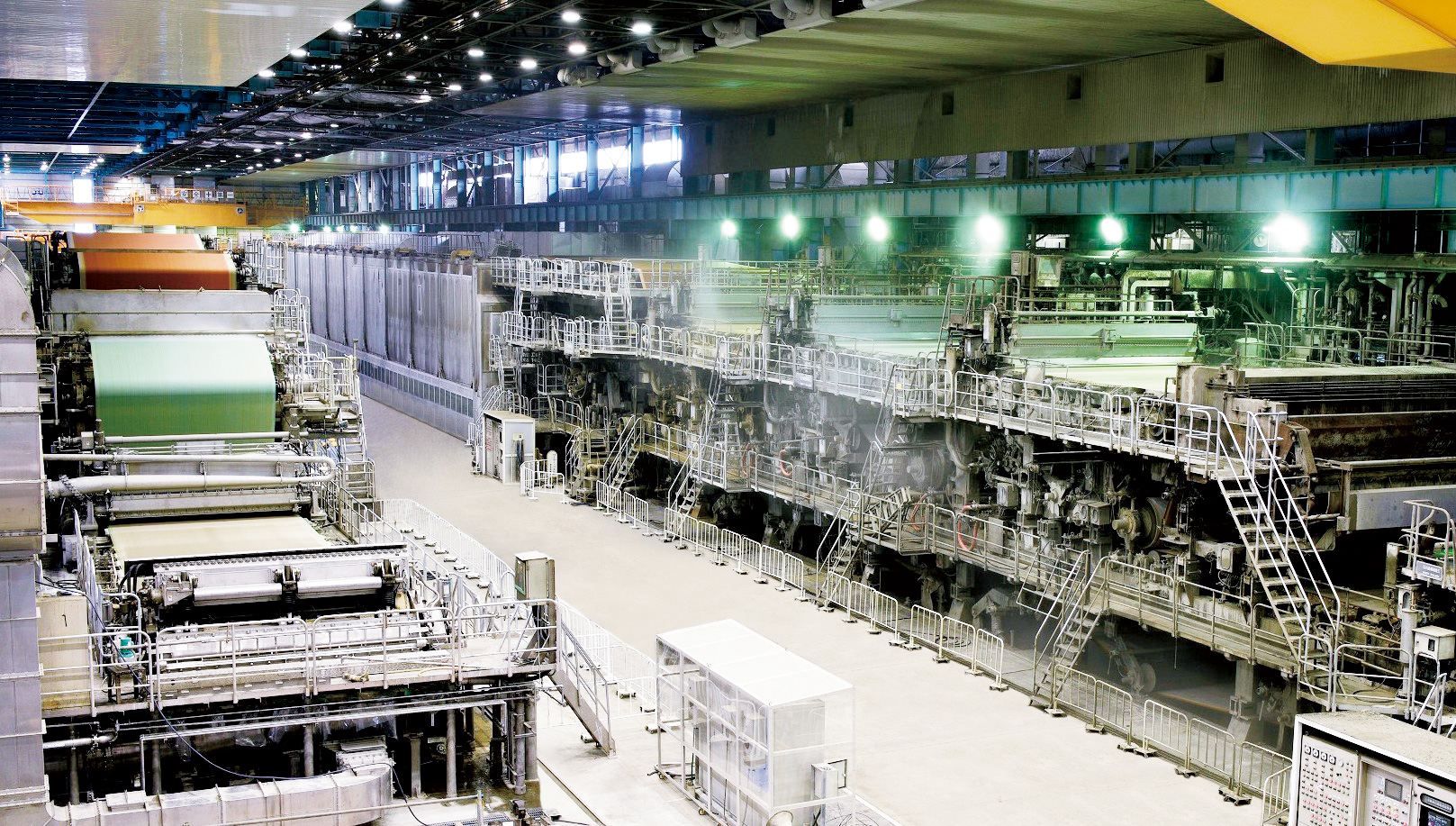

Paper machines No. 1 and No. 3 (cardboard manufacturing)

Paper machine No. 2 (newsprint manufacturing)

Products are shipped to cardboard processing companies

and newspaper companies

We believe in making environmentally friendly paper

and aim towards sustainable manufacturing through the use of

in-house power generated from recycled fuels.

- Pulp, Paper & Paper Products

- Area

Nakoso

- Industrial ParksYamada Industrial Park

IWAKI DAIO PAPER CORPORATION

Related Fields

-

Energy / Environmental Recycling

Company Overview

Our company was founded in 1996 as a subsidiary of DAIO PAPER CORPORATION, known for its elleair line of products. We manufacture cardboard and newsprint with the aim of making maximum use of recycled paper. As pioneers in the paper industry, we have introduced biomass boilers which use wood chips and RPF (refuse plastic fuel) and work to conduct ourselves as an environmentally conscious paper manufacturer.

Primary Products / Services

●Cardboard: Linerboard (unbleached/white), fluting

●Newsprint

IP & Licenses, etc.

Certifications / Licenses

●ISO 9001 (quality management systems)

●ISO 14001 (environmental management systems)

●ISO 27001 (information security management systems)

Awards / Commendations

●Nihon Keizai Shimbun - 16th Outstanding Cutting-Edge Business Establishment Award, October 1998

●8th Global Environment Awards - Ministry of the Environment

Minister's Award, March 1999

●Recycling Promotion Merit Awards - Minister of International Trade and Industry Award, October 2000

●Fukushima Protocol Business Manufacturing Industry Category - Grand Prize, February 2010

Company Strengths & Characteristics

Taking advantage of our location 180 km from the Tokyo metropolitan area, where most waste paper is generated, we procure a stable supply of fresh newspaper waste with good ink removability and recycle up to 600,000 tons of waste paper annually. Additionally, a portion of our factory's electricity is supplied by on-site power generation. The fuel used for this includes environmentally friendly biomass and waste- derived materials, such as wood chips from building demolition, refuse plastic fuel (RPF), waste tires, and vinyl materials removed from waste paper. By effectively utilizing waste paper through material recycling and recovering heat from waste as fuel through thermal recycling, we make contributions to a sustainable global environment.

Future Prospects & Areas of Interest

In addition to the stable operation of our newly constructed Recycling Boiler No. 5, which began operation in February 2023, by restoring our currently disabled Biomass Boiler No. 4 as soon as possible, we aim to bring our self-generation rate to 100%, become one of the most cost- competitive paper mills in Japan, and continue to provide a constant supply of low-cost, high-quality paper products to meet our customer’s needs. (Pictured on right: Recycling Boiler No. 5)

Company information

IWAKI DAIO PAPER CORPORATION

-

Representative

Hiroshi Okuyama, CEO & President

-

Established

April, 1996

-

Capital

100 (million yen)

-

Employees

200

-

Contact

Atsushi Shiraiwa, General Affairs Section Manager, General Affairs Department

E-Mail:atsushi.shiraiwa@daiogroup.com

Copyright ©︎2024 IWAKI MANUFACTURING COMPANY ARCHIVE All Rights Reserved.

-1024x682.jpg;)

.jpg)